The terms outsourcing and offshoring are considered a thing of the modern era of humanity. They were introduced and put into practice together in the 20th century, due to the process of the globalisation. By the early 1980s, both terms are featured in a business lexicon and they become a very common practice in the fabrication of goods.

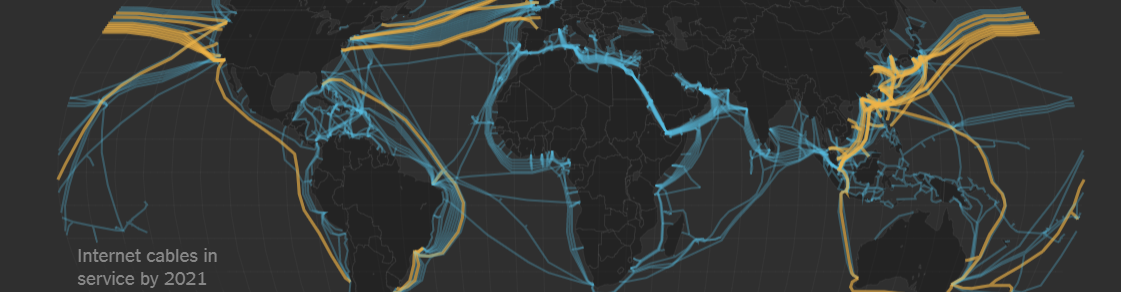

In the post WW2 era, a lot of companies started experiencing massive growth and the demand for their goods increased for a big percentage. While external providers were often able to provide the service quicker and more efficient, the heavy use of that practice only started towards the end of the 20th century, due to the massive communication, shipment and technology development. Working in other geographic locations, especially in developed countries where wages are lower, has become increasingly effective. This became known as offshoring. The practice called outsourcing however moves a part of the production into a foreign country – contracting work out to an external organization. [2]

Both practices have benefits and risks. Offshoring is useful as the production costs are usually much lower and done faster, while still retaining the quality of the products. Many criticise offshoring for transferring jobs to other countries, rather than employing the local people. That also introduces a geopolitical risk as the cultural and language differences are present.

Outsourcing on the other hand takes the advantage of specialized skills of foreign workers, lower costs and labour flexibility. But relying on third parties can for example introduce misaligned interests of clients and vendors, therefore the collaboration is not that efficient and beneficial.[3]

Many times both practices are combined and put to use together. This way the companies get the advantages of both of them. Sadly, often the environmental and fair labour issues are ignored, even though they are present. A big factor is a fact, that the third party managers don’t want to risk alienating their clients by raising issues of environmental responsibility and fair labour practices offshore.

The biggest environmental issue is of course pollution that is caused by fabrication. Outsourcing/offshoring transfers the problem to countries that already have a big pollution rate. The fabrication of outsourced goods and services contaminate the air, water, and soil, trigger deforestation and increases concerns about global warming. It also depletes labour and material pools and as a consequence endangers public health. [4]

Sadly, lower costs of fabrication lead to a higher, less regulated level of pollution. There are attempts from major companies to limit the effect that the two practices have on the environment, but it often takes them more than a decade to reach the desired level. But for many companies the profit is the most important thing, therefore they will pursue the most efficient way to increase their profits even if that goes against their true values. As George Bernard Shaw once said: “Lack of money is the root of all evil.” [1][5]

References:

[1] Sean Cubitt, “Ecologies of Fabrication,” in Sustainable Media: Critical Approaches to Media and Environment, eds. Nicole Starosielski and Janet Walker, New York and London, Routledge, 2016: 163-179.

[2] Strange, Roger & Magnani, Giovanna. (2017). Outsourcing, Offshoring And The Global Factory. 10.4324/9781315667379-4.

[3] Diffen, Offshoring vs. Outsourcing, Last accessed September 27, 2020, https://www.diffen.com/difference/Offshoring_vs_Outsourcing

[4] Ecommerce Times, 2004, Environmental Impacts of Outsourcing, Last modified October 19, 2004, https://www.ecommercetimes.com/story/37421.html

[5] Xiaoyang Li & Yue M. Zhou, Strategic Management Journal, 2017, Offshoring Pollution while Offshoring Production?, 2310–2329