FISAMA is a joint research project of Aalto University and VTT, funded by the Academy of Finland. It started in 2016/9.

Publications

Journal articles

- Paajanen, A. Vaari, J. High-temperature decomposition of the cellulose molecule: a stochastic molecular dynamics study. Cellulose, 2017. 24:2713-2725. doi:10.1007/s10570-017-1325-7

- Baroudi, D., Ferrantelli, A., Li, K., Hostikka, S. A thermomechanical explanation for the topology of crack patterns observed on the surface of charred wood and particle fibreboard. Combustion and Flame, 2017. 182:206-215. doi:10.1016/j.combustflame.2017.04.017

- Li, K. Mousavi, M., Hostikka, S. Char cracking of medium density fibreboard due to thermal shock effect induced pyrolysis shrinkage. Fire Safety Journal, 2017. 91:165-173. doi:10.1016/j.firesaf.2017.04.027

- Hostikka, S., Matala, A. Pyrolysis model for predicting the heat release rate of birch wood. Combustion Science and Technology, 2017. 189(8):1373-1393. doi:10.1080/00102202.2017.1295959

- Li, K., Hostikka, S. Embedded flame heat flux method for simulation of quasi-steady state vertical flame spread. Fire Safety Journal, 2019. 104:117-129. https://doi.org/10.1016/j.firesaf.2019.01.011

- Rinta-Paavola, A., Hostikka, S. A model for the pyrolysis of two Nordic structural timbers. Fire and Materials, 2020. https://doi.org/10.1002/fam.2947

- Adibaskoro, T., Makowska, M., Fortino, S., Rinta-Paavola, A., Hostikka, S. Elastic Modulus, Thermal Expansion, and Pyrolysis Shrinkage of Norway Spruce under High Temperature. Fire Technology, 2021. (accepted)

Conference papers

- Li, K. Mousavi, M., Hostikka, S. Char cracking of medium density fibreboard due to thermal shock effect induced pyrolysis shrinkage. 12th International Symporium of Fire Safety Science, Lund, Sweden, June 2017.

- Vaari, J. Building a reactive molecular dynamics framework for cellulose pyrolysis

studies. The 4th International Cellulose Conference, October 17-20,2017, Kyushu University School of Medicine, Fukuoka, Japan.

- Adibaskoro, T., Solowski, W., Hostikka, S. MPM simulations of wood with advanced multisurface material model. XIII Finnish Mechanics Days, 29-31 August, 2018, Helsinki, Finland.

- Rinta-Paavola, A., Hostikka, S. A Model for Pyrolysis and Oxidation of Two Common Structural Timbers. Forum Wood Building Baltic, 27.2.-1.3.2019, Tallinn, Estonia.

Posters

- Adibaskoro, T., Makowska, M., Fortino, S. and Hostikka, S. Elastic Moduli and Thermal Expansion Measurements of Norway Spruce via Dynamic Mechanical-Thermal Analyzer. 13th International Symposium on Fire Safety Science. April 19-30, 2021. University of Waterloo, Canada.

Thesis

Paajanen, Antti. Computational Studies on Cellulose : Pyrolysis, Nanostructure and Hydrodynamic Behaviour. University of Helsinki. Doctoral dissertation. 2020. http://urn.fi/URN:ISBN:978-951-51-5780-5

Scope

FISAMA -project deals with multiscale modelling of pyrolysis processes within bio-based materials in conditions relevant for fires. We try to tackle challenges related to

- Unresolvable phenomena in continuum scale pyrolysis modelling

- Hierarchical structure of natural materials

- Fundamental mechanisms of fire-retardancy

Objectives

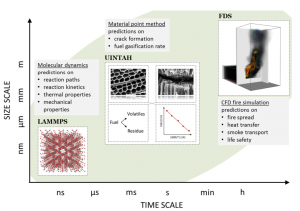

The overall goal is to improve the fire safety of bio-based materials by detailed analyses of their thermal degradation processes. Reflecting the physical scales of the problem, the project is divided into three work packages having goals of their own:

WP1 will aim at creating detailed understanding of the molecular level processes leading to the formation of either volatile or solid degradation products, in order to explain and optimize the use of chemical fire retardants.

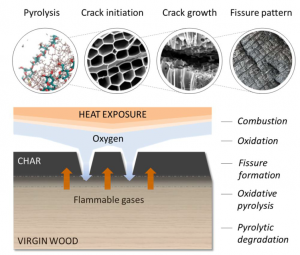

In WP2, we want to reveal the processes that lead to the formation of char fissures, and to propose physical means of avoiding them in order to strengthen the fire resistance function of the char layer.

Finally, in WP3, we will derive continuum-scale model parameters from the lower level models to apply the results in engineering calculations that demonstrate the real-scale impact of the small-scale findings.

Methods

- The molecular scale pyrolysis chemistry of cellulose, our primary polymer to be modelled, will be investigated using Reactive Molecular Dynamics (RMD) simulations. We are usnig code ReaxFF. The purpose of the RMD pyrolysis simulations is to investigate the thermal decomposition of cellulose at a molecular level, providing predictions of the reaction paths, as well as the associated chemical kinetics. The simulations can also be used to estimate the basic thermal properties of the system.

- The possibilities to improve the char layer stability will be investigated using Material Point Method (MPM) simulations. One of the codes used will be Uintah.

- As a third physical scale of modelling, we will use the continuum-scale pyrolysis model embedded within the Fire Dynamics Simulator software (FDS).

- Material characterization will take place using thermogravimetric analyses, mass spectrometry, differential scanning calorimetry, micro-scale combustion calorimetry, and SEM.

- For the validation purposes, we will use the experimental data from the University of Science and Technology of China.

Results

WP1

WP1 had two specific goals: (i) to evaluate the capability of ReaxFF-MD to predict details of the pyrolysis chemistry of cellulose, and (ii) to apply the method to study the operating mechanism of a known flame retardant. We used cellulose, which is a major component of plant matter, as a model compound for wood-based materials.

For the simulations, we chose the following bottom-up approach:

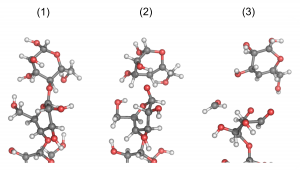

S1: Initial step of the thermal decomposition of individual cellulose chains (gas phase)

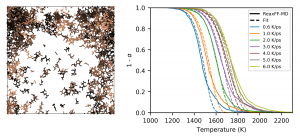

S2: Sequence of thermal decomposition reactions in native cellulose (condensed phase)

S3: Sequence of thermal decomposition reactions in phosphorylated cellulose (condensed phase)

In the single-chain simulations (S1), we observed that the decomposition begins with random cleavage of the glycosidic linkages, that the associated kinetic parameters are compatible with those obtained from global mass loss measurements of cellulose pyrolysis, and that several low molecular weight products characteristic of cellulose pyrolysis are formed. The results have been reported in [1].

Figure 1. Example of a decomposition event observed in the single-chain simulations.

The condensed-phase simulations (S2) confirm the observations of the earlier stage. We find that depolymerisation reactions, which constitute a rate limiting step in conditions of slow pyrolysis, can be described using an Avrami-Erofeyev type reaction model; that low molecular weight species are formed as direct products of ring fragmentation reactions; and that the reaction paths are similar in amorphous and crystalline cellulose. Notably, we do not observe the formation levoglucosan, which is a major volatile product of cellulose fast pyrolysis. The results will be reported in an upcoming publication.

Most of our observations are in favour of the ReaxFF-MD method, but the absence of levoglucosan suggests that extrapolating the results to conditions of practical interest might not always be possible. This complication, which we believe is due to the high temperatures used in the simulations, could be overcome through the development of acceleration methods for reactive molecular dynamics.

Figure 2. (left) Visualization of decomposing cellulose, and (right) progress of depolymerization as a function of temperature. The conversion variable α represents the fraction of cleaved glycosidic linkages. The dashed lines show an Avrami-Erofeyev type reaction model fitted against the simulations.

At the moment, the simulations on phosphorylated cellulose are still running. A summary will be added here once the results become available.